Here are different type cat litter machine:

1.Tofu cat litter machine

2.Bentontie cat litter machine

3.Crystal silica gel cat litter machine

4.Pine wood cat litter machine

Product ability:0.5-5 ton/hour

Depending on your product plan/budget/factory area,we will customize a suitable machine set for you.

For exmaple,customers form ample sunlight countries may don't need dryer machine.

Please feel free to contact us to know more information. The production process is as follows:

The production process is as follows:

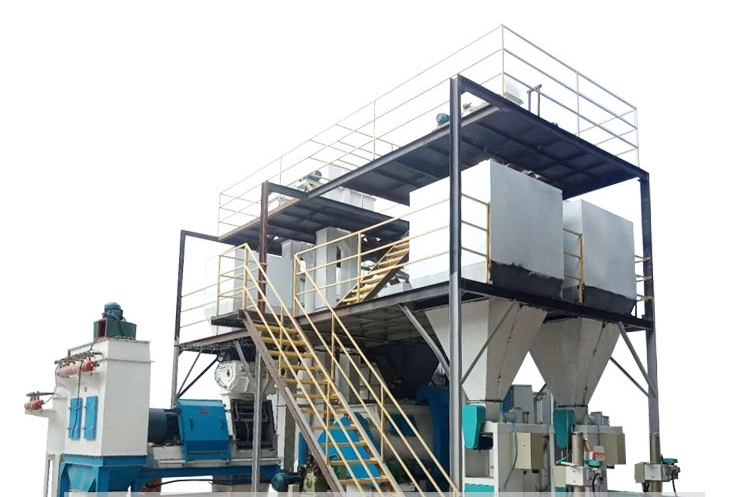

mixer - elevator - cone double feeder - single screw granulator - head for hot blowing -

isolating agent addition and recovery system - first stage cyclone separator - second stage

cyclone separator - extended air-cooled vibrating screen - finished product bin.

Equipment granulator Introduction:

The service life is more than five times of the ordinary granulator, wear-resistant, less wear parts, reasonable structure, easy to operate and maintain.

Automatic temperature control, wet and dry, coarse material, fine material.

Quick screen change, high efficiency and energy saving, completely reduce energy consumption, easy to process a variety of waste.

1.Complete specifications, high technical content, stable performance, low price, in the same industry LING first position.

2. Excellent mixing effect and easy temperature control.

3. Use less power and floor space.

4. The mixing and pelleting process of raw materials is fully automatic (automatic line control), reducing personnel operation.

5. This set of equipment does not require special operation technology, producing high-quality products and simple operation.

6. Excellent safety.

7.Temperature control is easy, so the damage and deterioration of raw materials are reduced.

8. New energy-saving granulator

9. Provide investors with professional granulation technology, plastic modification technology, color matching technology and formula, each formula can process different quality of particles at the same time.

Before we give you the professional recommendation, please confirm the following information:

Requirement and specification:

1. Name of the raw material ?

2. Size&Moisture of the raw material?

3. How many raw material you have one day?

4. How many hours you want to working per day?

5. What's the output you need?

6. What's the kind of the final product you need? ( the shape, diameter, length)

7. Usage of the final product ?

8. Electric motor or diesel engine?

Pre-sale service:

Provide customers the parameters and confirm necessary technical points

Share photos and videos with clients

Show our factory to clients for checking

On-purchase service:

Keep clients informed of the production progress

Send photos to clients before shipment for checking

Arrange the visa for engineers who will go for guide assembly

After-sale service:

Training and all-around technical guidance for operation, commission and maintenance

Engineers abroad to for guide assembly

Detailed drawings from front view, vertical view, side view

people with the aim that Serving For World and Bringing.Our Product To The Global Gradually. We are willing to assist new customers to grow and regular customers to boost sales.